Benchtop Crimping Machines_TE

Applicator & Product Style:

- Heavy Duty Mini (HDM)

- Mid Wire Size

- OCEAN

- Splice

Categories: APPLICATION TOOLING, TE, Tools

- Classification: TE, TE plier, Benchtop Crimping Machine, Benchtop Crimping Tool, Crimping Tool

- Applicable ends: 2161400-5, 2217000-2, 2161300-1, 2161700-4, 2161700-5, 2161500-2, 2217000-1, 2161300-2, 2-2161500-2, 2161500-1, 2844800-1 , 2-2161500-1

- Benchtop Crimper for Low- to Medium-Volume Wire Processing.

- Our extensive line of bench-top wire crimping machines provide flexibility, performance, and reliability for low to medium volume wire processing. The Model G II+ features the most advanced design in the long-standing series of AMP-O-LECTRIC machines for terminating wire using reeled terminals. AMP 3K and 5K Terminators are powerful, economically-priced machines that yield the increased output and quality of a semi-automatic machine. The AMP-O-LECTRIC Model G II Terminator with Thru-Splice Applicator is designed to apply thru-splices by providing access to both sides of the applicator that place the wires to maximize production efficiency.

Related products

Salient features

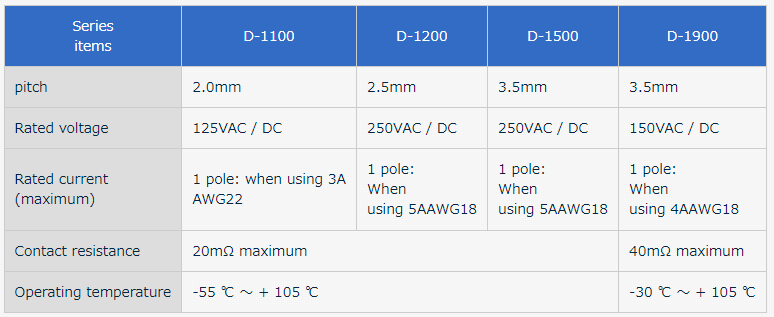

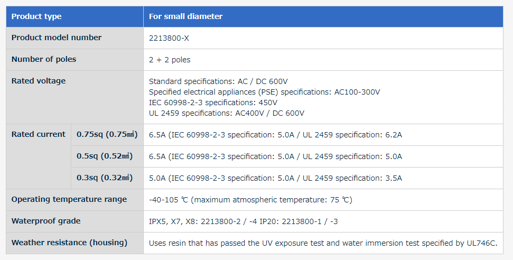

The smallest multi-pole signal connector in the dynamic series. Further miniaturization of industrial equipment can be realized.

An abundant series lineup is also a major feature. Available in pitches of 2.0 mm, 2.5 mm, and 3.5 mm. As for the color version, in addition to the standard color of the dynamic series so far, black, yellow and natural colors are also available. In addition, there are various features such as contacts that can handle a wide range of electric wires and crimping tools that can replace dies.

Note

Salient features

Using Heat Shrink Tubing

Heat shrink tubing provides electrical insulation, mechanical protection, environmental sealing, and strain relief for applications such as back-end connector sealing, breakouts, and connector-to-cable transitions. It is a solid alternative to taping, molding, or potting. When heated, our Raychem heat sleeves conforms to the size and shape of the substrate beneath, enabling quick and easy installation. Its high expansion ratio makes it possible to repair most damaged cable jackets without removing connectors. Available in a wide range of materials, colors, and sizes, heat shrink tubing is delivered in forms such as spools, 1.2m lengths, and cut pieces. Clear types permit inspection of covered components and offer excellent transmittance of light.

Note

Wall Material Type

Fiber & Fabric

Pre-Coated Tubing

Pre-Coated Wrap Jacket

Salient features

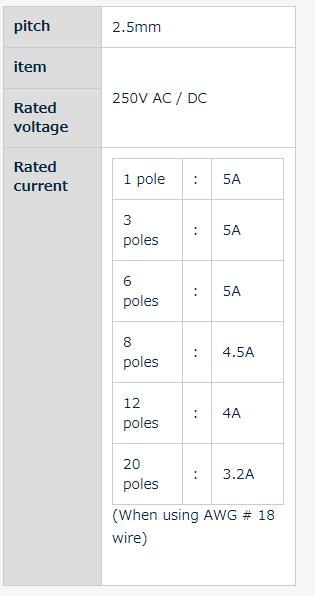

A connector that is compact in the dynamic series but has achieved specifications for industrial equipment.

It can be used mainly for signal applications.

It has an appropriate pitch of 2.5 mm for signal lines of 250 V or less, and is compatible with AWG # 18 wires at this pitch. (1 pole maximum 5A)

In addition, it has various features such as a center lock method that enables effective use of the board and a contact lance for low profile rolls.

Note

Salient features

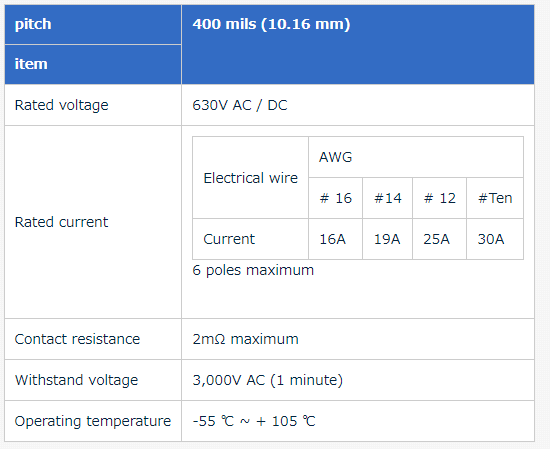

The D-5000, which has the largest connector size in the dynamic series, is being developed with the aim of becoming a dedicated power connector for industrial equipment.

As with the D-3000 series, a newly developed copper alloy is used for the contacts to support high power, achieving 30A per pole.

The pin arrangement is 10.16 mm (400 mil), which allows a large pattern to be taken in consideration of the high current of the board type.

In addition, a high current α series has been added. Supports up to 45A per pole.

Note

Salient features

- Classification: NICHIFU, NICHIFU VIETNAM, NCF VIETNAM, NICHIFU DISTRIBUTOR, pneumatic crimping, crimping

- Piston motion crimping dies make terminal not to rotate in the dies. NA10 (0.3mm2~5.5mm2) NA20 (8mm2~60mm2)

Note

- PNEUMATIC TOOL : NA 10, NA 3, NA 20

- HYDRAULIC HEAD : NP 1000

Salient features

- Classification: PANDUIT, PANDUIT DISTRIBUTOR, PANDUIT DISTRIBUTORS, PANDUIT VIETNAM, CABLE TIE TOOL, CABLE TIE, TOOL

- Panduit Manual Cable Tie Installation Tools

- Tool controlled tension provides flush cut-off and speeds

- Lightweight and balanced ergonomic design

- Excellent tools for low to medium volume applications

- Easy to change tension adjustment and easy to operate

- QPL per Mil. Std. SAE AS81306 and Mil.

- Spec. SAE AS90387

- For Use With: For Panduit SM, M, I and S cross-section cable ties

- Pneumatic Cable Tie Hand Tools

- Panduit Automatic Cable Tie Installation Systems

- The complete line of Panduit automatic cable tie installation systems offers a superior solution for high volume harness, assembly, fastening and packaging applications. These ergonomic systems increase productivity, provide consistent performance, and reduce activities that lead to repetitive motion injuries

Note

- For Use With: For Panduit SM, M, I and S cross-section cable ties

- Standards Met : QPL per Mil. Std. SAE AS81306 and Mil. Spec. SAE AS90387 Mil. Spec. (Part Number MS90387-1)

Salient features

Super simple wiring!

No special tools required: Universal pliers can be used.

No need to strip the wire coating: Just cut the wire to the required length and install it as it is

Side-by-side wiring: Even one person can do the work of connecting the relay between the power source and the load.

Transparent body: You can visually check whether the wiring is correct or not.

Wide range of applicable wire: Applicable to single wire, tinned wire and braided wire size from 0.3 to 0.75 sq

Revolutionary waterproof structure

Simple: Revolutionary waterproof construction with silicone-based hydrophobic gel filled inside the connector

Submerged: IPX8 Compliant * * Cleared flood test at a depth of 1m / 2 hours

High weather resistance: UV resistance can be used outdoors (UV resistant plastic is also used for housing)”

Note

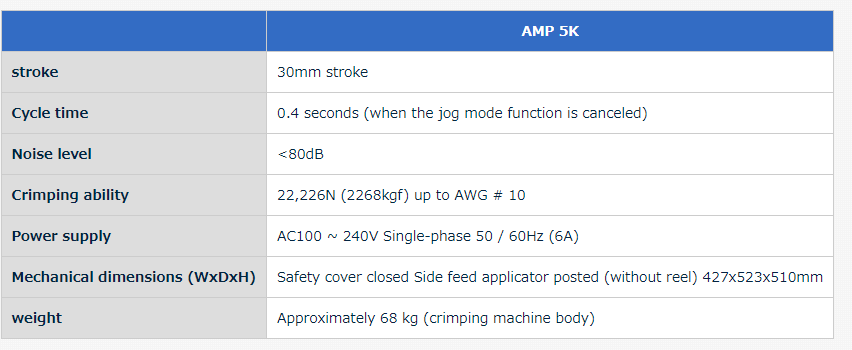

Salient features

Noise is reduced by adopting a DC motor

Noise is reduced by adopting a DC motor direct drive system. You can easily adjust the speed of the motor.

It also supports step movements with the jog button, improving workability such as checking the operation of the applicator and adjusting the terminal feed.

A wide range of compatible options, compatible with applicators made by other companies

A wide variety of options are available to support a wide variety of crimping operations. You can also replace the applicator quickly. It is compatible with applicators made by other companies and is easy to replace.

Prepare a safety cover

If the safety cover opens while driving, it will stop instantly. You cannot resume work until you close the safety cover.

Not only does it ensure the safety of workers, but it also prevents accidents caused by malfunctions during applicator replacement.

Other features

・ Crimping height can be adjusted in increments of 0.013 mm within a range of ± 0.25 mm

・Can be used at AC100 to 240V

・ A wide variety of options are available according to the work environment

Note